Biochar as Building Material for Optimal Indoor Climate

by Hans-Peter Schmidt

A wine contains up to 1000 different substances, though their individual functions are by no way completely known. Why does a vine take the trouble to produce such an enormous chemical library in every grape? And what happens with all those molecules between harvesting the grapes and filling the wine into bottles?

Even if we take into serious account the unknown panoply of molecules in the wine, wine is not just a composition of organic-chemical formulas and minerals, but a living elixir. We should not forget that most of the organic molecules in wine have been degraded, converted and made more complex through the activity of yeasts, bacteria and enzymes. Wine is the result of not just chemical, but also biological processes. And that's what makes each wine unique.

When making wine naturally, a large proportion of the yeasts and bacteria responsible for converting the grape juice to wine are transported from the vineyard to the cellar on the skins of the grapes and in the grapes themselves. And this is one of the main reasons why the promotion of biodiversity and the avoidance of synthetic and biological pesticides play such a decisive role in determining the quality of a wine. The yeast and bacteria flora are essential elements of the terroir, responsible not just for fermenting the sugar to wine but also for providing the enormous complexity and wide range of different aromas of each wine. At least on account of this role, they need to be protected.

The influence of cellar climate on natural wine making

The microorganisms entering the cellar together with the grapes are all too often a minority species in the cellar. This is because spores and microorganisms from past wine-making seasons are to be found on the walls and floor of the cellar and on all vats and tools. As soon as the fresh grape juice is poured into the vats, these spores and microorganisms reawaken and immediately start work on unchecked proliferation, encroaching on the "Lebensraum" of the still "inexperienced" yeasts and bacteria fresh from the vineyard.

Anyone wanting to make a natural wine and unwilling to have recourse to selected yeasts must therefore take utmost care to preserve the microbial flora, not just in the vineyard but also in the cellar. Each wine cellar has its own microbial flora. And these exercise the same amount of influence on a natural wine as the famed terroir on which the grapes are grown. This is basically no different to those traditional cheese dairies which, when moving premises, wash down the walls of the old diary and then daub the washing water on the walls of the new dairy, thus taking with them their old and trusted microbial flora.

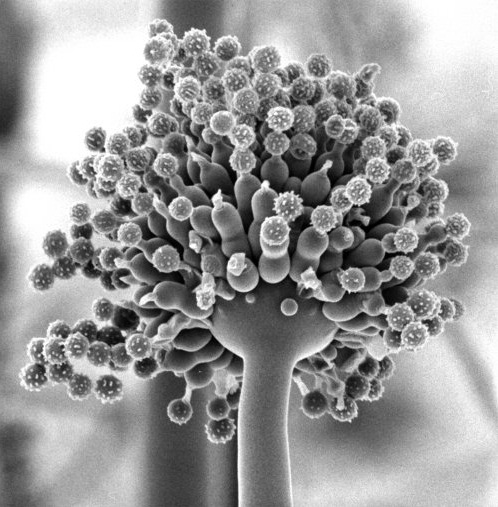

We will find on the walls, vats and machines of a wine cellar not only the desired yeasts and bacteria, but also countless other more or less useful, neutral or harmful microbes and spores. One of the main worries here are the countless species of moulds such as penicillium, cladosporium or alternaria. These moulds are a danger not just to the wine on account of their metabolites, the so-called mycotoxins, but also to the health of the people working in the cellar.

Black, blue, green, white and orange moulds, invisible to the naked eye, can develop, especially when high humidity levels lead to condensation on the walls and vats. To prevent this, high humidity levels and temperature fluctuations must be avoided at all costs in the cellar. However, instead of making sure that the cellar has an optimal climate with a humidity level of 60 - 75%, many cellars rely on sterilising substances, the effect of which is often unsatisfactory as they kill off not just the harmful but also the beneficial microbial flora, as well as contaminating the cellar with often questionable chemical substances.

Common moulds in a wine cellar Alternaria alternata (left) and Aspergillus flavus (right)The last 50 years have seen cement-based materials used for building new and modernising traditional cellars. The surfaces have then been sealed with washable paint or tiles. The result might be pleasing from a hygiene perspective, but it is fatal for the microbial flora in the cellar. The sealing of walls and floors and the use of cement-based plaster means that the cellar walls are no longer able to breathe and can hardly adsorb any moisture. After hosing down the cellar or after lowering the temperature by a few degrees, condensation occurs on the walls, leading in just a few days to the sporulation of various species of mould.

Common moulds in a wine cellar Alternaria alternata (left) and Aspergillus flavus (right)The last 50 years have seen cement-based materials used for building new and modernising traditional cellars. The surfaces have then been sealed with washable paint or tiles. The result might be pleasing from a hygiene perspective, but it is fatal for the microbial flora in the cellar. The sealing of walls and floors and the use of cement-based plaster means that the cellar walls are no longer able to breathe and can hardly adsorb any moisture. After hosing down the cellar or after lowering the temperature by a few degrees, condensation occurs on the walls, leading in just a few days to the sporulation of various species of mould.

The use of biochar-clay plaster in cellar refurbishment

To achieve a cellar climate best promoting the natural microbial flora that have made their way into the cellar from the vineyard, tests were made at the Delinat Institute on ways of restoring and refurbishing wine cellars in a sustainable manner. One of the main project aspects involved the development of a plaster based on biochar and clay. A new method of application saw the walls of an old Valais wine cellar being sprayed with a 10 cm thick layer of the new biochar-clay plaster (see photo). This massive wall coating provides not only good thermal insulation and consequently fewer temperature fluctuations, but is also a great humidity regulator.

In combination with the right ventilation, the machine-sprayed plaster made of clay and biochar is able to keep cellar humidity levels at a constant 60 - 80% throughout the year, thus preventing or at least greatly reducing the development of mould and other harmful microbes. At higher humidity levels, the walls quickly adsorb moisture, returning it to the room just as quickly when humidity levels drop. While too high a level of humidity promotes the development of harmful microbes, too low a level is also not beneficial, as it leads to particulate pollution, electrostatic charging of the air and the evaporation of wine in wooden barrels.

The biochar-clay layer of plaster acts as a moisture storage buffer, whereby the capability to adsorb water is dependent on the thickness and quality of the biochar-clay plaster. When high doses of moisture regularly reach the cellar through the earth or by hosing down the cellar, even this buffer will at some stage reach its capacity. This means that the cellar also needs a good natural source of ventilation.

The ingredients of the biochar-clay plaster

To make the spray plaster, 30 - 50% biochar is mixed into the clay, to which a certain amount of sand has been added (compared with normal clay plasters, the sand content is slightly lower). The biochar-clay mixture thus contains 50% biochar, 30% sand and 20% clay. This mixture can also be used as an intermediate layer of plaster, whereby the biochar is ground to less than 5 mm particle size. The result is an anthracite-coloured plaster with a very noble, slightly shimmering appearance. Should a lighter colour be desired, the share of finely ground biochar is reduced to 10-20% for the top layer, and clay-based paint applied as the final coating. No problems have been encountered either with applying the plaster or with its hardening. Compared to lime- or cement-based plasters, the biochar-clay mixture is even beneficial for the hands of the building workers, meaning that gloves and protective clothing are not needed.

It is intended to bring a range of biochar-clay plasters to the market by mid-2013. Up till then, the focus will be on optimising the mixtures and conducting a series of measurements with regard to final solidness, thermal conductivity and water storage capacity.

Biochar can just as well be mixed into conventional lime- or cement-based plasters in equal proportions. In doing so, the biochar can help increase their insulation and water storage capacities. The same applies to rendering. However for plaster, clay is the recommended basic material for achieving an optimal indoor climate.

After applying the intermediate layer of plaster, the biochar gives the plaster an anthracite colour with a slightly shimmering appearance. After the final layer of plaster has been applied, clay-based paints can be used as final coating.

After applying the intermediate layer of plaster, the biochar gives the plaster an anthracite colour with a slightly shimmering appearance. After the final layer of plaster has been applied, clay-based paints can be used as final coating.

Thanks to its huge surface and porosity, the biochar in the clay plaster helps to adsorb contaminants, spores and mycotoxins as well as helping to bind the gases produced during vinification. The latter aspect means that the moulds and other bacteria lose their feeding grounds. Optimal humidity and the binding of toxins are perfect for promoting healthy microbial flora in the cellar, protecting the wine against sensory deficits. The experience gained in the first winter season in the Valais test cellar shows that the humidity levels have remained constant at 65 - 75%.

The spraying method developed together with the German company, Casadobe, for applying thick layers of biochar-clay plaster can be used both for restoring old cellars and also for refurbishing modern concrete cellars. And of course it can be used for the construction of new cellars. Through the experience gained in this first refurbishment project (to be continued in the coming year with scientific measurements of cellar flora and indoor climate) we hope to have come up with a natural way of optimising a cellar's climate.

Biochar-clay plaster for use in homes

The biochar-clay plaster technology developed by the Delinat Institute to refurbish wine cellars can also be used for other enclosed spaces, such as food stores, animal housing, warehouses or even houses and offices. Optimal humidity levels have a major influence on the well-being and health of the inhabitants of houses and offices. A humidity level below 40% can lead to dry mucous membranes, in turn increasing the risk of colds, asthma and allergies. Similarly, a humidity level above 70% in closed living spaces results in increased exposure to mould spores. Applying just a 2 cm layer of biochar-clay plaster can noticeably improve a room's climate. Two Valais houses have already been restored using biochar plaster. First experiences with indoor use have proved to be extremely promising.

If biochar-clay is used as construction material for plaster, insulation or bricks, buildings could partially be recycled after some hundred years as a soil conditioner instead of becoming hazardous waste.

PS.: Biochar-clay plasters also have a shielding effect with regard to electromagnetic radiation ("electrosmog"). This means that we have no GSM reception in the test cellar, a further positive feature allowing us at least there to fully concentrate on working with nature.

amr

2013-04-08 11:59

is biochar-clay efficient as thermal insulation and how can i make it

hps

2013-04-08 13:04

yes, its one of the best thermal insulator for buildings. You will find clay-sand plaster on the market, you just have to mix it with biochar up to 50:50 on a volume base.

amr

2013-06-14 12:46

i am egyptian and i can not find clay_sand plaster so how can i make it by myself

hps

2013-06-14 15:43

Clay-sand (adobe) is one of the oldest building materials in Egypt but you might be right that you only find Portland Cement in Egypt these days. Either you make it like the ancient on your own (clay-sand is just underneath your feat if you don't live in the dessert). Otherwise you could also make biochar plaster or brigs with chalk or with cement (1:2:1 - cement: biochar : sand).

http://en.wikipedia.org/wiki/Adobe

The word adobe /əˈdoʊbiː/ has existed for around 4,000 years, with relatively little change in either pronunciation or meaning. The word can be traced from the Middle Egyptian (c. 2000 BC) word dj-b-t "mud [i.e., sun-dried] brick." As Middle Egyptian evolved into Late Egyptian, Demotic, and finally Coptic (c. 600 BC), dj-b-t became tobe "[mud] brick." This was borrowed into Arabic as al-tub (الطّوب al "the" + tub "brick") "[mud] brick," which was assimilated into Old Spanish as adobe [aˈdobe], still with the meaning "mud brick." English borrowed the word from Spanish in the early 18th century.

Adobe style in Santa Fe, New Mexico

Cheers, hp

amr

2013-10-31 20:58

if i want to use biochar as thermal insulator .the prefect layer is 2cm or more or less

hps

2013-11-02 19:38

... we apply sometimes up to 20 cm as it's not only an insulator but also a buffer for heat and humidity.

Simone

2014-02-07 10:44

Danke für die interessante Information zum Thema Lehm. Kann man eigentlich auch eine Schicht Lehm unter der Tapete verwenden, um das Eindringen von elektromagnetischer Strahlung zu verhindern? Es wird in letzter Zeit eine spezielle Tapete für diesen Zweck hergestellt, aber Naturprodukte sind uns sympathischer.

hps

2014-02-07 10:56

Sie sollten vorher sicher einige Tests mit geeigneten natürlichen Tapetenkleber durchführen, aber Pflanzenkohle-Lehmputz funktioniert auch unter Tapeten, gerade was elektromagnetische Strahlung betrifft.

hps

2014-04-10 22:41

sure, it's also great for temperating the place in hot climates. You can apply 10 to 20 cm of plaster without any problem.

amr

2014-05-10 13:12

does rain affect the layer

hps

2014-05-11 13:13

If you use biochar-clay plaster on the outside it would have to impregnated (e.g. with oil)

Alois Muff

2014-06-16 07:40

Bin interessiert an Pflanzenkohle für den Mörtelbereich.

Gibt es diese in verschiedenen Körnungen und welche Festigkeit hat die Pflanzenkohle? Ist Versuchsmaterial erhältlich?

hps

2014-06-16 22:46

Im Mörtelbereich setzen wir für den Unterputz Pflanzenkohle mit einer Partikelgröße von 0 bis 20mm ein, wobei der Feinanteil (0 - 2 mm) überwiegt. Im Oberputz setzen wir gemahlene Kohle (0 - 2 mm) ein. Diese Pflanzenkohle finden Sie bei allen EBC zertifizierten Herstellern von Pflanzenkohle.

W. Schindler

2014-06-20 15:35

Wir interessieren uns für die Lehmputz-Mischung mit Pflanzenkohle.

Gibt es in Deutschland (vorzugsweise in der Region Leipzig) Verarbeiter mit entsprechender Erfahrung, Material-Bezugsquellen bzw. die Möglichkeit den Umgang mit dem Material zu erlernen?

Soll zu Testzwecken in einem Nebengebäude/Lagerraum eingesetzt werden.

hps

2014-06-21 14:12

Die Verarbeitung von Pflanzenkohle zur Verwendung als Baumaterial ist nicht allzu schwer zu erlernen und wir erwägen im September einen Workshop für Hand- und Heimwerker durchzuführen, damit sich diese effiziente und schöne Technik rasch weiterverbreitet. Zur Zeit sind uns leider noch keine Handwerker ausserhalb des Wallis bekannt, die schon Erfahrung mit dieser Technik haben. Gern würden wir hier bald eine Liste publik machen mit Handwerkern, die die Arbeit in dieser Technik in den verschiedenen Regionen anbieten.

Kurmann Sacha

2017-05-22 09:37

Guten Tag.

Wir bauen mit Stampfleh, Lehm u.s.w.

und möchten ein Holzhaus mit Wandheizung verputzen.

Das Pflanzekohle- Lehmgemisch wäre in meinen Augen der ideale Putz.

Für den Energienachweis, müssten wir Angaben bezüglich dem Lambda-wert des Putzes haben. Haben Sie diesbezüglich Daten? kann man die Pflanzenkohle mit einem Werklehmgrundputz mischen? z.b. von Claytec.

Besten Dank für Ihre Antwort, und wir wären an diesem Putz sehr interessiert.

Freundlichst Kurmann Sacha

hps

2017-05-23 05:27

Wir haben leider noch immer keine Lambda-Werte für die Putze. Es kommt ja auch sehr stark auf die Putzmischung an und müsste eigentlich für jede Mischung gesondert durchgeführt werden. Für die Behörde würde ich die Lambda-Werte von Claytec nehmen, die Kohle macht es dann auf jeden Fall nicht schlechter. Und ja, die Mischung mit Claytec-Grundputz klappt gut. Bei dickeren Schichten ist ein Hanf- oder Basaltnetz zur Vermeidung von Rissen zu empfehlen. Grüsse, hp schmidt

wes

2018-02-21 23:45

Hello, I am interested in more of the material properties of biochar as used for building materials. It is stated that it is a good insulator, but not what it's U value (or RSI) value is, so I was wondering what that was. Also I am concerned about flammability when used as plaster. Has there been any fire tests performed at all?

Cheers,

Wes

hps

2018-02-22 05:56

Hi Wes, unfortunately, we still do not have the U value which is not so easy to measure as it depends on the quality of the biochar (mainly pyrolysis temperature and feedstock) and the water content. We are dependent here on our partners as we are not equipped at Ithaka for this type of experimental set-up. When biochar is used in plasters, they are impossible to be inflammed independent if you use clay, lime or cement as plaster binder. There are tests that showed that biochar improves the fire resistency of concrete based building materials. However, do never use biochar as pure insulation filler between walls but only within plasters, bricks, concrete, etc. When used pure as bulk material, it can explose when humid.

Best, Hans-Peter

Michael Künzler

2018-11-23 03:55

Guten Tag,

Gratuliere für die innovativen Techniken.

Meine Frage: Eignet sich diese Technik auch für eine Art "Blumentöpfe"?

Ich wohne seit 14 Jahren in der Nähe von Goiania, Brasilien und plane hier eine Bio-Gärtnerei. Werde in einer ersten Phase mit einem Gewächshaus (5000m2) beginnen. Ich möchte Biochar Humus herstellen und diesen in ca. 1m hochgestellten 40m langen Pflanzenbeeten verwenden. "Tische" 1m x 40m mit je 4 Kanälen zu 25cm. Mit Tröpfchen-Bewässerung-Schlauch (Humus wird nicht nass, nur feucht). Die Kosten für "konventionelle" Hochtische sind mir zu hoch (Holz- oder Metallunterbau, PVC Rohre, Styropor, Keramik oder ähnliches). Daher möchte ich leichte Pflanzenbeet-Elemente herstellen (1mx70cm) und diese auf gespannten Drahtseilen (40m mit Stützen) aneinander reihen. Welche Mischung wäre möglich um solche Elemente herzustellen? Ich habe Sand und guter Lehm auf dem eigenen Grundstück. Denke aber, dass wohl eher Zement in Frage kommt wegen der Humusfeuchtigkeit.

Anforderungen an die Elemente: einigermassen leicht, einigermassen stabil (3-4 Drahtseile unter dem Element als Auflager), biologisch verträglich wenn möglich, nicht extrem wasserdurchlässig, ansonsten habe ich bei 35 Grad einen "Verdunster" durch den Elementboden. Lebensdauer der Elemente 2 Jahre oder mehr.

Gibt es atoxische Imprägnierung? Zementlösung?, fetteres Gemisch? (Ansonsten Plastikfolie über die Elemente)

Ich werde auf jeden Fall einige Experimente machen, aber währe froh, wenn sie mir ein paar Tips geben könnten dazu. Do's and Dont's… (Ich habe Altpapier-Zement Elemente analysiert, aber das wird toxisch und benötigt dann sowieso ein Plastik Folie darüber.)

Klima: Subtropisch. 6 Monate sehr trocken und heiss (25-38 Grad). 6 Monate wechselhaft: Recht Feucht bis sehr Trocken, Warm-Kalt (15 - 38 Grad)

PS: Ich bin generell interessiert, ihre Techniken in Brasilien zu verbreiten. Brasilien benötigt das dringend. (7L Giftkonsum via Essen pro Jahr). Ich habe nächstens ein Meeting mit einem Uni-Professor, spezialisiert auf organischem Gartenbau. Werde natürlich ihre Techniken vorstellen. (Selbst: 3 Jahre Architektur Studium ETH Zürich, 5 Jahre Erfahrung mit "konventioneller" Gärtnerei in Brasilien)

Schmidt, Hans-Peter

2018-11-26 08:18

Blumentöpfe bzw. Pflanzkästen mit einer Mischung aus Pflanzenkohle, Sand und Zement herzustellen, ist eine gute Möglichkeit, um Gewicht zu sparen. Man kann zwar den Sand auch komplett mit Pflanzenkohle ersetzen, aber in dem Fall würde sich die Kohle dann doch mit der Zeit etwas Wasser aufnehmen. Allerdings wäre das Gewicht des aufgenommenen Wassers immer noch leichter als Sand. Was in Ihrem Klima für die Pflanzen am besten ist, müssen Sie einfach ein bisschen ausprobieren. Ich würde zunächst folgende drei Mischungen probieren:

1 Teil Pflanzenkohle : 2 Teile Sand : 1 Zement

2:1:1

3:1

Für einen Erfahrungsbericht mit Bildern wären die Ithaka-Leser Ihnen dankbar.

Viel Erfolg, Hans-Peter Schmidt

Hans Söhl

2018-12-11 06:35

Ich hab mir mal eine Form gemacht um solche Töpfe herzustellen.

Die Töpfe habe ich aus Holzkohel - Zement und Holzkohle - Gips hergestellt.

In einem Topf, der stand in meinem Büro auf dem Fensterbrett, hatte ich 3 Jahre lang eine Kartoffelpflanze.

Die Töpfe im Freien haben dem Frost nicht standgehalten. Ein Nachteil ist, wenn die Töpfe von der Sonne beschienen werden verdunsten sie sehr schnell alles Wasser das im Topf enthalten ist. Werden die Töpfe im Boden vergraben kann man die Wasserspeicherfähigkeit der Töpfe gut beobachten. Das Problem bei den ersten Töpfen im Boden war der hohe Nährstoffbedarf um die Holzkohle mit ausreichend Nährstoffen aufzuladen. Deshalb habe ich die Töpfe vor der Verwendung immer mit Urin getränkt, das heißt untergetaucht und einige Tage ziehen lassen. Danach sind die Töpfe getrocknet, anschließend mit einer Kompost – Erdemischung gefüllt und bepflanzt worden.

Was ist die logische Schlussfolgerung?

Mit einer Gießform habe ich eine Einwegkomposttoilette hergestellt. Die Schritte der Nährstoffanreicherung und Befüllung mit Kompostmaterial sind damit ohne zusätzliche Arbeit erledigt! Das Teil ist befüllt und steht seit drei Jahren in der Mitte meines Gartens. Es hat schon so manchen zum Schmunzeln gebracht.

Viele Grüße Hans Söhl

hps

2018-12-11 08:33

Um Frostschäden zu verhindern, sollte in die Gußform der Töpfe ein Basaltnetz eingelegt werden. Ein Hanf- oder sonstiges Netz wie es für Lehmputze verwendet wird, geht auch.

Wenn man den Topf auf einen Unterteller stellt, welche gegossen wird, saugt sich der gesamte Töpf mit Feuchtigkeit auf, so dass die Topferde gleichmässig von allen Seiten mit Wasser versorgt wird. Da ein Teil der Feuchtigkeit über die Aussenwände des Topfes verdunsten, kühlt dies den Topf, was je nach Standort ein Vorteil oder Nachteil ist. Auf jeden Fall ist es ein wunderbarer natürlicher Feuchtigkeitsspender für die im Winter gar zu trockenen MinEnergy-Häuser.

Schöne Grüsse den Experimentieren und besten Dank an Hans Söhl, seine Erfahrungen zu teilen, Hans-Peter

German

2020-01-23 18:02

Hello and thank you for the wonderful research!

I would like to use this myself and was wondering if you know how the % of biochar in the mixture affects humidity levels? I want to use this as indoor plaster in a tiny house, and would like to promote a humidity level of around 45%.

Thank you

hps

2020-01-24 14:20

Unfortunately, we do not have hard data on it. We use 50 - 70% (vol) biochar in the plaster and reach good humidity levels. However, 45% would be too dry for inside climate. For the health, better to have arround 60% humidity. Best, hp

Ray

2020-05-06 10:10

Hi, I am currently producing a quite good amount of biochar for soil rehabilitation purposes, but I also want to try to apply it for other purposes, in this case, energy efficient buildings. I am living in Indonesia (exactly on the equator) where the humidity reaches 95% at its peak; it is a problem for us. My questions are: if biochar plaster can easily absorb moisture, where did the moisture go afterwards? doesn't it (the wall) becomes wet/damp after a while? and if it does can control humidity, for how long does the plaster can do that? do we need to renew/replaster the wall after certain times?

Your guidance will be much appreciated - any statistics will also be helpful on this.

Thank you

hps

2020-05-18 09:37

Well, biochar can only absorb humidity until its saturation. If there would always be 95% humidity, the buffer capacity of the biochar would quickly be limited. However, as even in Indonesia there are dryer periods when the biochar plaster can dry, the buffer capacity is restored. Another advantage is that the biochar plaster will not produce mold like it is the case for cement-based materials.

Unfortunately, we do not have any reliable scientific data on biochar based materials and humidity control in the tropics. If you do trials, please be so kind as to inform us about it. Kind regards, Hans-Peter

Franz

2021-02-18 15:10

Gibt es irgendwelche Aussagen zum U-Wert von Pflanzenkohle-Lehmputz?

hps

2021-02-23 08:38

Das hängt leider von vielen Faktoren wie Feuchtigkeit, Pflanzenkohle-Anteil, Pflanzenkohle-Eigenschaften usw. ab und muss systematisch untersucht und ausgemessen werden, was leider bisher noch nicht durchgeführt werden konnte.